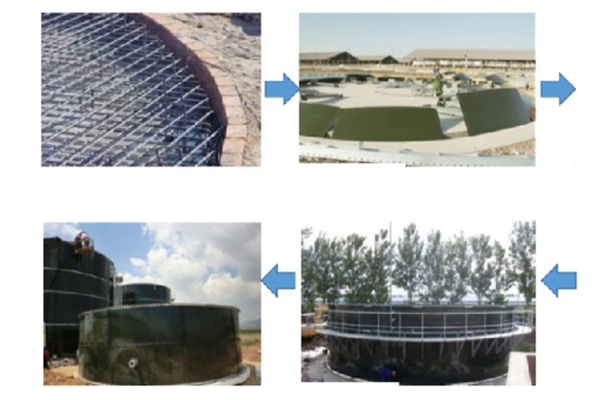

GFS Tanks Characteristics, Benefits and Applications

The term vitreous enamel is derived from the term vitrification, which refers to the transformation of a substance into a transparent glass.

Vitreous enamel is fired at typical vitreous enamel firing temperatures, which are typically in the range of 830-850°C, until the coating reaches its maximum mobility and viscosity.

It is during this time period that the interaction between the glass and steel accelerates, an interfacial adhesion layer is formed, and the synthesis of the two materials occurs.

In order to provide clients with a high-performing, cost-effective coating that is specifically designed for the containment of potable water and uncovered municipal wastewater tanks, GFS Tanks developed a manufacturing process that incorporates the latest technology.

GFS Tanks Features and Benefits

- A one-of-a-kind and highly sought-after glass formulation created with bespoke ingredients.

- Electrostatic application that is unique in that it is ‘dry.’

- Glass enamel coating technology has reached a new level of excellence.

- Optimal purity is achieved.

- There will be less reliance on on-the-ground solutions.

- Coating coverage has been increased.

- This product meets or exceeds the coating requirements of EN ISO 28765.

- System that is modular in design.

- Confidence in the quality and performance of the coating.

- Construction is completed in a short period of time.

- Quality that is consistent and regulated no matter where the tank is shipped or built.

- Confidence in the quality and performance of the coating.

- Coating with excellent performance.

- There is no requirement for re-coating.

- Corrosion resistance is built in and specified.

- The coating has a long life span and requires little maintenance.

- There is no corrosion allowance required, resulting in the reduction of unnecessary material and cost.

- The ability to be UV stable and abrasion resistant extends the life of the product and reduces the need for through-life maintenance.

Glass Fused to Steel Tanks Applications

- Agricultural digesters are used in agriculture.

- Borehole/brackish/seawater.

- Bulk solids that are dry.

- Fire Protection Water Storage Tanks

- Storage of firefighting water.

- Tanks for filtration.

- Processing of industrial effluent and aeration.

- Leachate is a liquid waste product.

- Sludge storage in municipal facilities.

- Sludge treatment in municipal settings.

- Municipal mesophilic digesters are a type of mesophilic digester.

- Storage of sludge cakes in municipal facilities.

- Drinking water that is safe to consume.

- Storage of sludge cakes in municipal facilities.

- Drinking water that is safe to consume.

- Storm water is a type of water that falls from the sky.

- Thermophilic digesters are those that digest at high temperatures.

We Have Cover Following Markets:

GFS Tanks offering design, manufacture, and supplier of Glass-Fused-to-Steel Tanks and Zincalume Tanks around the Globe and having happy customers spread across:

- USA: Montana, Florida, South Dakota, New Jersey, New Mexico, Alaska Nevada, Texas, etc.

- Europe: Austria, Poland, Monaco, Sweden, Finland, Croatia, Malta, Andorra, Albania, Italy etc.

- Middle East: Jordan, Syria, Kuwait, Oman, Israel, Saudi Arabia, Egypt, Yemen, Cyprus etc.

- Indian Areas: Himachal Pradesh, Assam, Gujarat, Mumbai, Delhi, Orissa, Madhya Pradesh, Karnataka, Rajasthan, West Bengal, Punjab, Haryana, Andhra Pradesh, Bihar, Hyderabad, Telangana etc.

- Others: Maldives, Myanmar, Nepal, Bangladesh, Bhutan, Pakistan, China etc.